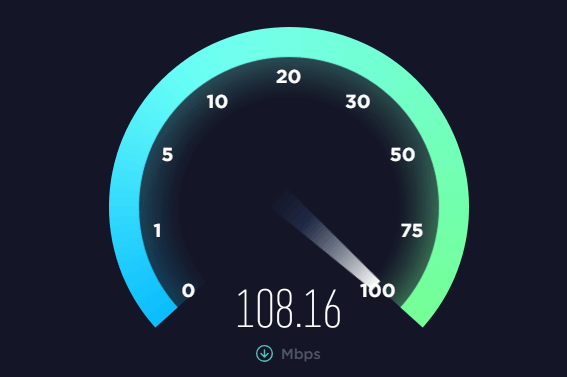

I wanted to make a ultra lite image that I can quickly drop Go programs onto. This image had a few requirements, be under 300MB, have less than 20MB ram usage idle, startup in under 5 seconds. I will post below everything I did to strip this down so that it can be replicated in the future. Currently with the steps below I have achieved 427MB/16MB, close to my goal for disk and memory usage is below the goal. As for bootup time, I am limited by network connection time 5+ seconds.

Install a fresh Raspbian Stretch Lite image into the SD card (source).

Configure headless SSH and Wi-Fi (if necessary) before starting the SD card (source).

[Read More]